Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

1. Definition and overview of copper etching

Copper etching is a unique process that involves the intricate carving and processing of copper. This technique allows copper to be intricately carved into a variety of beautiful patterns and shapes, enhancing the visual appeal of our lives. The principle behind this technique relies on chemical reactions, where specific etching solutions react with copper to achieve the intricate carving. This technology is widely used in the creation of artworks and has also brought numerous benefits to the industrial manufacturing sector. The essence of copper etching is to selectively remove copper on the surface of copper through chemical reaction, and then carve out specific patterns.

2. Key parameter analysis in etching

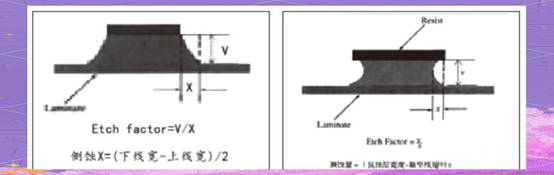

Etch factor: it measures the ratio between the vertical etching depth and the lateral side etching width, that is, the anisotropy of etching.

Side etching: This refers to the horizontal distance change between the outermost edge of the copper foil on one side and the innermost edge of the copper foil in the etching process, that is, the dimensional change of the copper foil in the transverse direction.

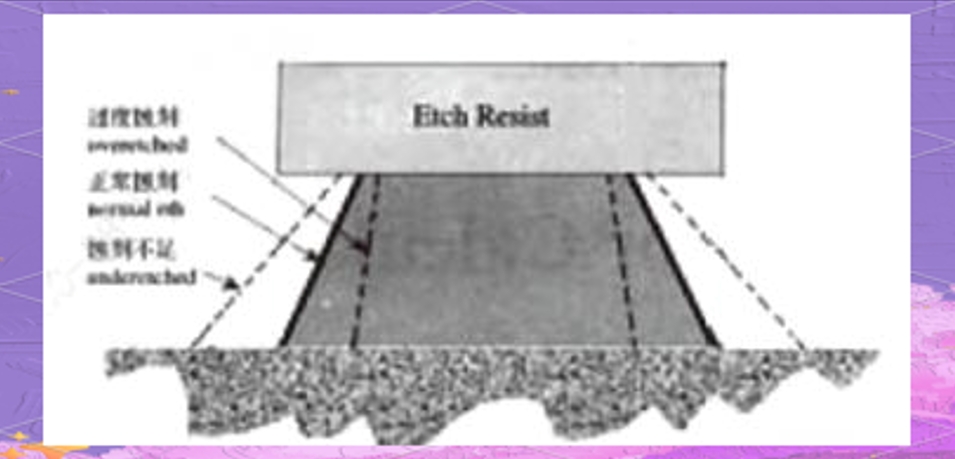

When there is no excessive etching, the side etch is equal to half of the difference between the lower and upper line widths. However, when there is excessive etching, the side etch refers to the minimum distance between the two arcs at the waist of the line, as illustrated in Figure X. Depending on the post-etching line shape, the side etch is often referred to as the burr size. Additionally, the etch factor can be calculated by dividing the copper thickness by the side etch.

3. Glossary

Coating agent: an organic additive added to the etching solution.

When the water flow is weak, it can form a film attachment on both sides of the line, thus reducing the erosion of the medicine on the line and reducing the impact of side erosion.

4. Detailed explanation of etching process

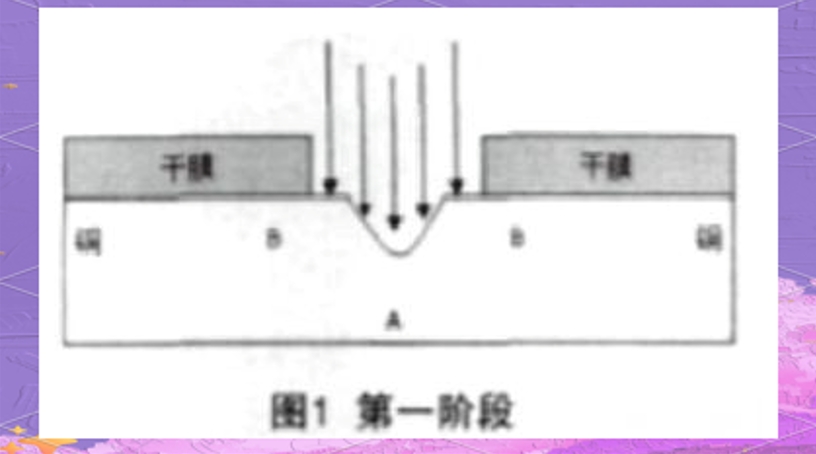

In the initial stage of etching, the copper that is not protected by dry film is initially etched.

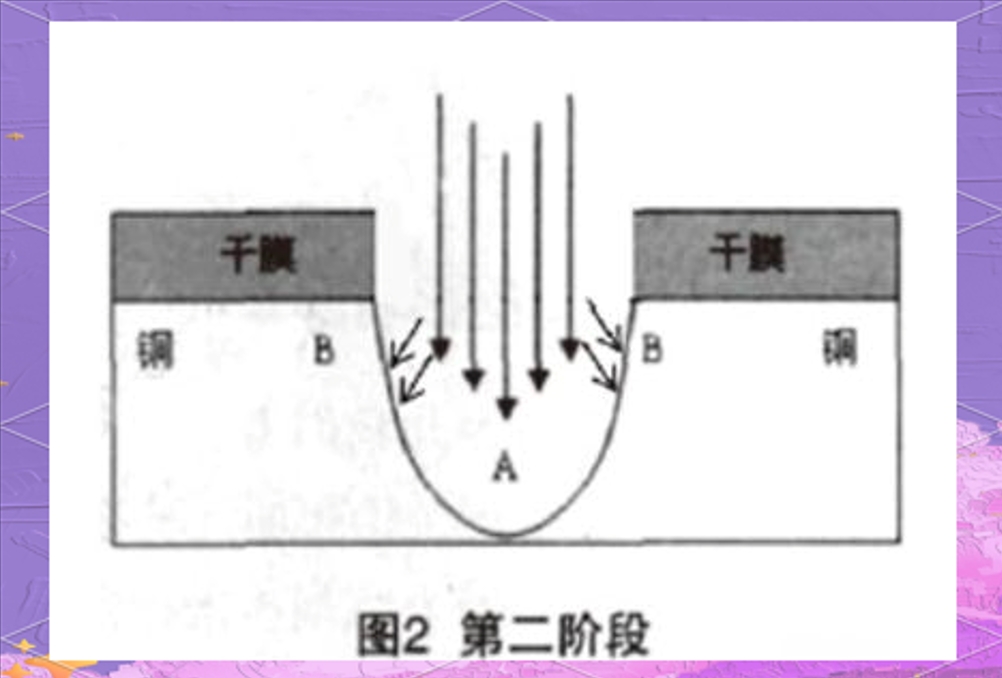

The second stage involves the completion of copper layer etching between the lines, at which point the copper between the lines is completely removed. During this phase, the inhibitors and shore protectors in the etching solution have not yet fully taken effect, so the etching efficiency is primarily influenced by the etching equipment's capabilities and the etching parameters. Additionally, the etching process in this stage involves both longitudinal and transverse directions. The strength of the longitudinal etching capability directly affects whether the etching can reach the bottom of the copper layer, which in turn influences the size of the burr.

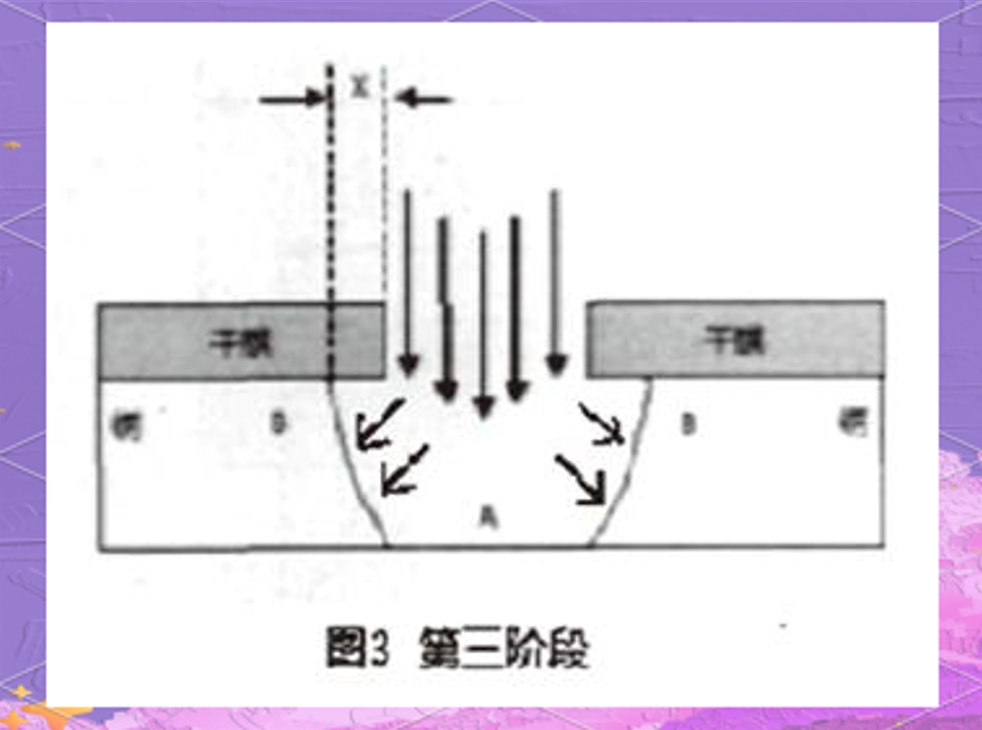

The third stage is the line formation phase, during which side erosion begins to occur.

At point B, the shore protection agents and inhibitors in the etching solution start to work, preventing the lateral spread of etching. As the etching process continues, the concentration of CuCl, which is not easily soluble in the solution, gradually increases. Due to the barrier effect of the dry film, the rate at which fresh solution is replaced at point B is much slower than at point A, causing the etching rate to gradually decrease. In contrast, the rapid exchange of solution at point A maintains a high etching rate. As the etching process continues, the copper layer is progressively eroded, increasing the amount of etching and reducing the burr formation.

5 . Evolution of etching effect

During the etching process, over time, the line shape will exhibit three distinct states: under-etching, normal etching, and over-etching. In the case of over-etching, the burr phenomenon is indeed reduced to a minimum; however, at this point, the line width has already fallen below the preset requirement.

The etching factor, which is revealed by this calculation formula, reveals the key factor in the etching process, namely the ratio of copper thickness to side etching. In the etching process, if the line thickness is kept constant, then the key to improving the etching factor lies in reducing side etching, which is usually referred to as burr size.

6. Factors affecting lateral erosion.

① Etching time: the longer the stay time in the etching machine, the greater the etching amount, so as to reduce the roughness of the circuit.

② Equipment performance and etching parameters: the stronger the longitudinal etching ability, the smaller the burr.

③ Copper thickness difference: under the same etching conditions, the thicker the copper thickness, the larger the line burr.

④ Etching solution composition: The difference in the composition of shore protectants and inhibitors from different suppliers will affect the results of etching factors.

⑤ Copper tooth size: the larger the copper tooth, the larger the burr.

7. Improvement methods of over-etching.

Although burr is the smallest when over-etching, the line width will be smaller than required. Therefore, the copper layer line width can be increased to compensate for burr, and then over-etching can be performed to improve burr. However, it should be noted that excessive compensation may lead to the risk of poor exposure or incomplete etching.

May 23, 2025

If you want to have a lively, lively and energetic home improvement, you will naturally find wall decorations. Many people like to hang decorative paintings, photos, etc. on the walls of the living...

As the brightness of the unit continues to increase, LEDs are becoming more and more widely used in the field of lighting. In order to continuously increase the brightness of the LED, it is...

Chip ceramic capacitor 6035 18.432 ceramic TDK Co., Ltd. (President: Kazuyuki Kazuhiro) developed a new ceramic capacitor, New MEGACAP Type, which supports a high-reliability lead frame with a lead...

As the brightness of the unit continues to increase, LEDs are becoming more and more widely used in the field of lighting. In order to continuously increase the brightness of the LED, it is...

Email to this supplier

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.